Permanent Magnet Screw Air Compressor

1. The PM and EPM range of SCR screw compressors’ unique oil-cooled permanent magnet motors offer the highest motor efficiency ratings.

2. SCR’s oil-cooled motors utilize the compressor oil lubrication system for cooling the engine throughout the whole frequency range ensuring the motor temperature remains cool even at low-speed running. Adequate motor cooling avoids high-temperature demagnetization problems often associated with Permanent Magnet technology. SCR’s PM motor is rated at 180 degrees Celsius, effectively avoiding demagnetization issues

3. SCR’s PM motor is a fully enclosed IP65 structure, eliminating any dust or liquid ingress. This fully enclosed IP65 structure protects the motor even in the harshest environments.

4. The unique PM motor design offers reduced maintenance due to the bearing-free motor design.

5. New generation super profile airend

SCR’s Super profile airend, reduces air leakage and increases the compression area, exceeding the national level of energy efficiency by 8%-10%.

Due to the excellent safety performance and high-efficiency ratings, this makes SCR’s airend the customer’s first choice of airend.

6. Original “Morse” connection

The airend and motor use a “Morse” connection, making any future air end maintenance convenient and straightforward. This contact method avoids any motor damage, significantly reducing maintenance costs.

7. Touch screen intelligent controller

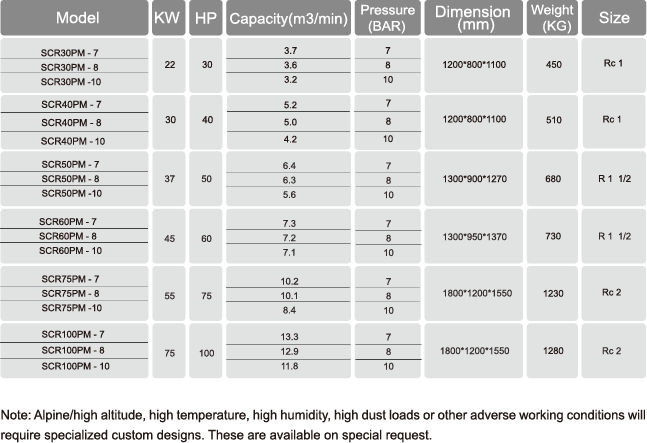

Technical Parameters

Model: SCR30PM~SCR100PM

Power:22KW~75KW

Capacity:3.5~13.3m3/min

Pressure:7~10bar