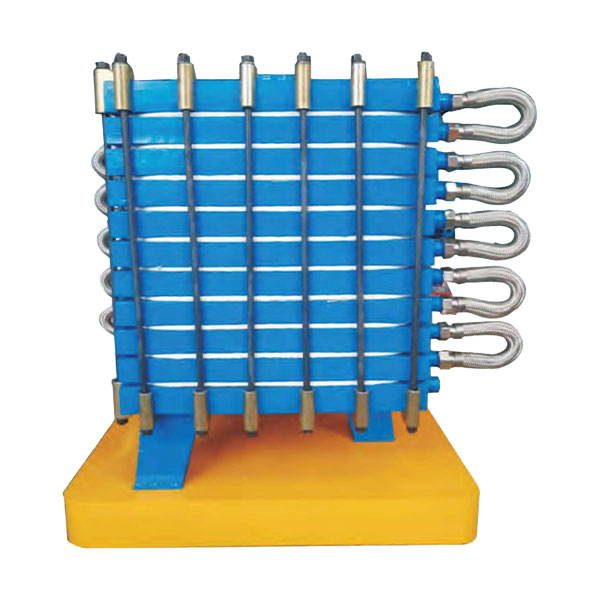

Glass-lined half pipe coiled reactor

The contrast of half pipe-coiled pipes Glass lined reactor and out jacket glass lined reactor:

1.Vessel type and Safety:half pipe-coiled pipes glass lined reactor is belong to stationary heating or cooling operation.For the safety,half pipe-coiled pipes glass lined reactor is more safer

2.The effect of heat transfer: Although the heat exchange area of outside half pipe-coiled pipes is 1/3 smaller than the outside jacket, the flow rate is 2 to 3 times quicker than the outside jacket, in fact, improve the effect of heat transfer.The outside jacket have some problem such as the heat transferring medium is easy to form disturbance flow, short circuit, nonuniform heat exchange and so on.However, outside half pipe-coiled pipes do not have these fault. So, for the liquid heat or cold medium,the effect of heat transfer of outside half pipe-coiled pipes is more remarkable.Similarly,for cooling applications,the half pipe jacket significantng reduces the required cooling water flov and pump pressure to achieve the same cooling capacity as a conventional jacket. In addition, for the steam heat style,considering the influence of pipe group,the outside jacket is better.

3.Stiffness:half pipe-coiled pipes strengthen the stiffness of the reactor, outer half coil belongs to open type heating trandfer method with high speed flow, reducing the outer pressure for the inner jacket body,increacing the stiffness of the reactor actually

4.The contrast of corrosion resistance:While using the cooling water,the corrosion can be easily formed under the ion erosion of ion H+、CL-,which will lead the solution precipitation and corrosion when we are in the condition of using out jacket type;If we use the half pipe-coiled pipes,the precipitation will not easily formed with the help of high speed flow with the upper-lower path.Of course,the pipe wall will not be corroded

搪玻璃半管夹套与整体夹套性能对比优缺点:

1.容器类别和安全:整体夹套方式属于固定加热或冷却带压作业,半管夹套方式属于液态流动加热或冷却作业方式。就安全性而言,半管夹套方式更安全(不属于固容规的监管范畴)。

2.换热效果:半管夹套方式换热面积虽然比外夹套小约1/3,但流速可以提高到外夹套方式的2~3倍,实际增加了换热效率,整体夹套方式换热介质易形成扰流、走短路、换热不均匀,半管夹套方式不存在此缺陷。所以对液态加热介质、冷却介质半管夹套方式效果显著。同样,对于冷却应用,半管夹套设计也能够大幅度减少所需冷却水流量和所需的泵压力,以获得常规夹套相同的冷却能力。对于蒸汽加热方式,考虑到半管夹套方式管阻影响,半管夹套方式优于整体夹套方式。

3.刚度:半管夹套增强了反应釜的刚度,半管夹套属于开式高速流动换热方式,减小了对内套筒体的外压,实际增强了反应釜的刚度。

4.耐腐蚀性对比:在使用冷却盐水冷却时容易形成对金属的H+、CL-离子腐蚀,整体夹套方式容易形成溶液沉积而发生腐蚀;半管夹套方式采用下进上出高速流转不易形成沉积,结垢不易对管壁造成腐蚀。