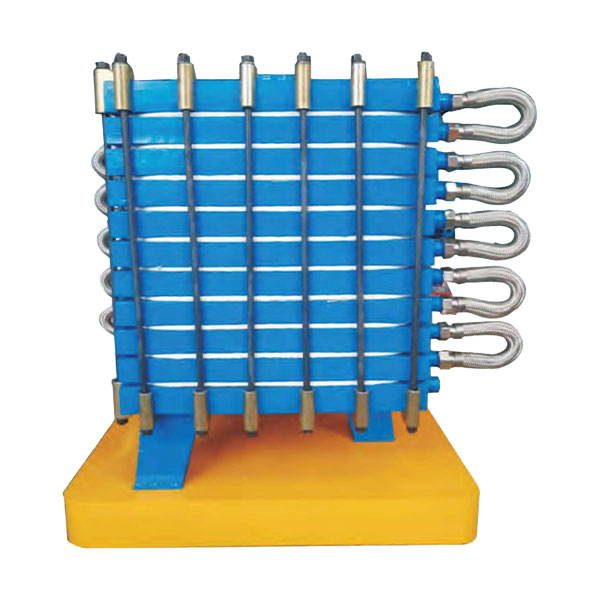

Class lined three-in-one equipment

Glass-lined washing, filtering and drying three-in-one equipment is a batch-type fully enclosed process equipment for solid-liquid separation, washing and drying, which is widely used in chemical, fine chemical and pharmaceutical process industries. The washing, filtering and drying three-in-one equipment includes a cylindrical barrel + upper head and a removable or fixed flange-connected bottom cover for supporting the filter plate, and a stirring drive device that can be raised and lowered is installed on the top. This filter often works under pressure or vacuum inside, with a heating jacket and a stirrer, and a bottom discharge valve.

Glass-lined washing, filtering and drying three-in-one equipment is designed for solid-liquid filtration (separation) under pressure or vacuum, and realizes dynamic filtration during the stirring of crystallization liquid; smoothes the filter cake to avoid cracks and grooves to ensure good washing; washes the filter cake by suspension or displacement; slowly squeezes the filter cake to reduce humidity; dries the filter cake-discharges the dry material through a special side discharge valve.

High stability and wear resistance to highly corrosive media. Suitable for products that are sensitive to metal, pollution or temperature. Wide operating temperature and pressure range. An alternative to Hastelloy. Low investment cost. High returns. The side discharge valve adopts PTFE or FEP sealing ring soft seal. In order to ensure the sealing of the side discharge valve, it is equipped with automatic or manual sealing surface cleaning device. The main flange is fixed with hook-shaped clamping ring bolts. The filter medium is PTFE filter plate or filter cloth. Double-end mechanical seal is suitable for chemical or aseptic process. *CIP and SIP system. Manual or fully automatic tail material discharge device. Meets GMP standards and FDA specifications.

搪玻璃洗涤过滤干燥三合一设备是在化工、精细化工和制药流程工业中应用广泛的批次式的用于固液分离、洗涤干燥的全密闭工艺设备,洗涤过滤干燥三合一设备包括一个圆柱形筒体+上封头和一个可拆卸或固定式的法兰连接的底盖,用于支撑过滤板,在顶部装有可以升降的搅拌驱动装置。这种过滤机内部经常在压力或真空下工作,带有加热夹套合搅拌器,还带有底部放料阀。

搪玻璃洗涤过滤干燥三合一设备是专为固体-液体在压力或真空下过滤(分离)而设计的,在搅拌结晶液的过程中实现动态过滤;抹平滤饼以便避免裂缝和沟槽,保证良好的洗涤;通过悬浮或置换洗涤滤饼;缓慢挤压滤饼以便降低湿度;干燥滤饼-通过特殊的侧面排料阀排出干燥的物料。

对强腐蚀介质的高稳定性和高耐磨性·适合于对金属、污染或温度敏感的产品·操作温度和压力范围大·是替代哈氏合金的选择·投资成本低·高收益·侧面排料阀采用PTFE或者FEP密封圈软密封·为了保证侧面排料阀的密封性,装有自动或者手动密封面清洗装置·钩形卡环螺栓固定主法兰·过滤介质为PTFE过滤板或滤布·双端面机械密封适合于化工或无菌工艺·*CIP和SIP系统·手动或者全自动尾料排净装置·符合GMP标准和FDA规范要求。