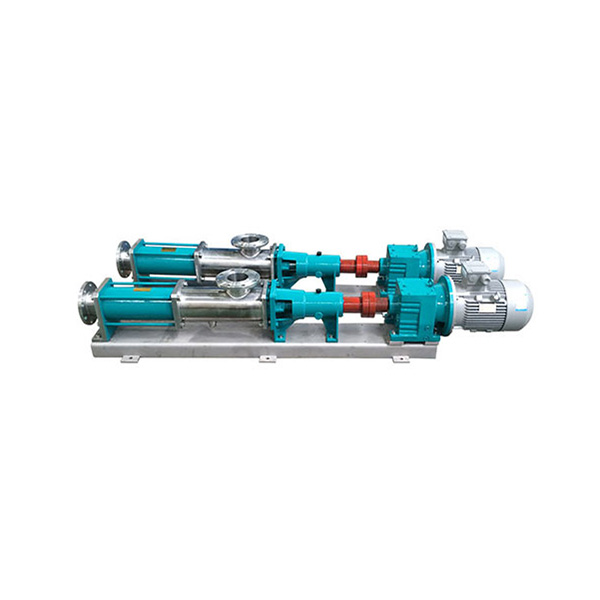

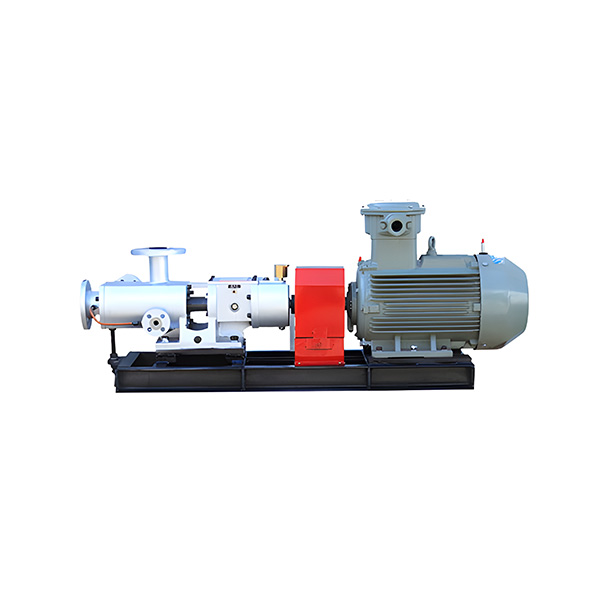

Hopper screw pump

overview

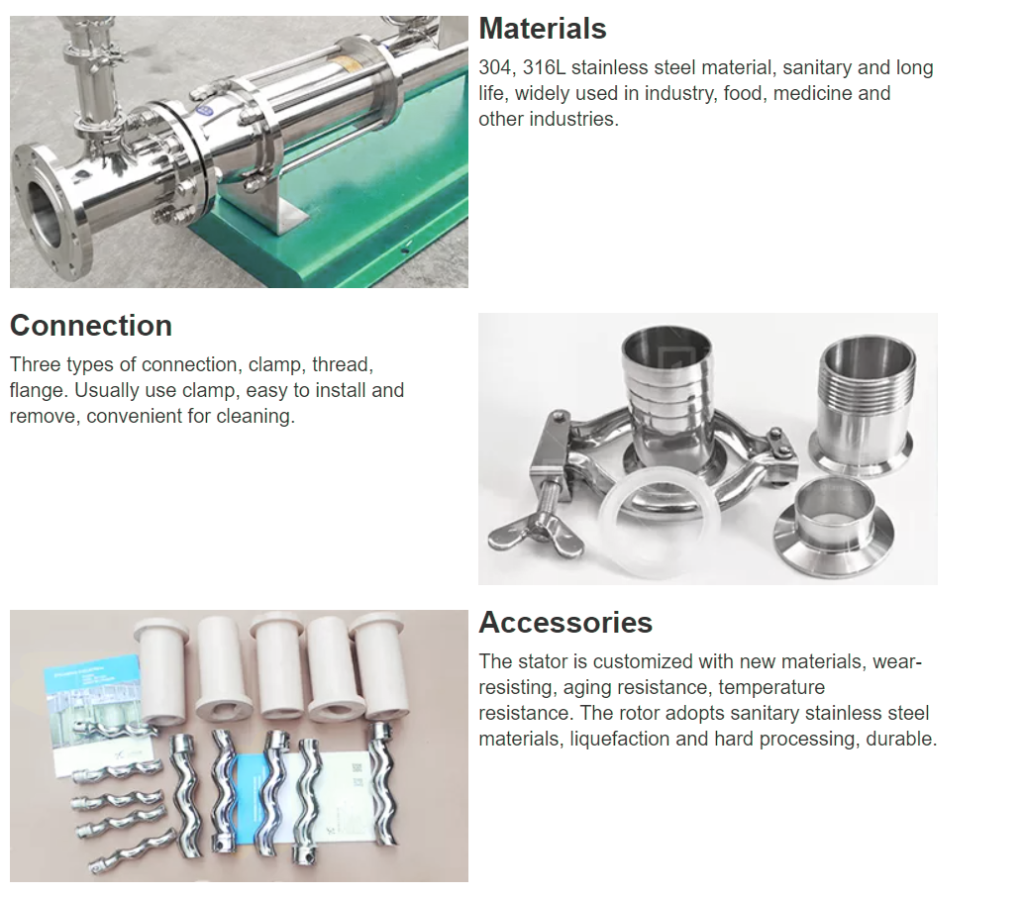

The hopper screw pump has a rectangular hopper and a screw propeller on the connecting rod, which is suitable for media that cannot flow freely but contains liquid. When transporting similar slag liquid, a stirring rod can also be installed to prevent sedimentation. When the slag concentration is high, add a large funnel that can be kneaded and damaged to prevent clogging. The pump can be equipped with various types of drives, suitable for three-phase geared motors. According to customer requirements, the hopper can be customized at the entrance for special materials, insisting on the smoothness of the feeding, and then reaching the feeding and discharging without pressure, higher pump power and longer service life, completely affirming the customer’s problems. The import and export methods can be equipped with clamp quick-installation type, flange type, internal thread, external thread, and union. Pump body materials can be divided into: cast iron, stainless steel 304, stainless steel 316, 316L, selected according to the actual medium requirements.

Application

Products are used in petroleum industry, chemical and pharmaceutical, environmental engineering, mineral engineering, food industry, papermaking and other industries.

Suitable medium

- High solid content (diameter of the biggest particle is 50mm) or no solid content

- Medium with all viscosities (1mPas~3,000,000mPas)

- Medium that is easy to be generated and swelled

- Shearing sensitive medium

- Medium with erosion

- Medium with/without self lubrication

- Erosive medium (PH=0-14)

- Adhesive medium

- Toxicity hazard medium

Voltage:220v/380v/440v;

Warranty:1year, 12 months;

Power Source:Electric;

Customized support:OEM;